From industrial site to circular innovation

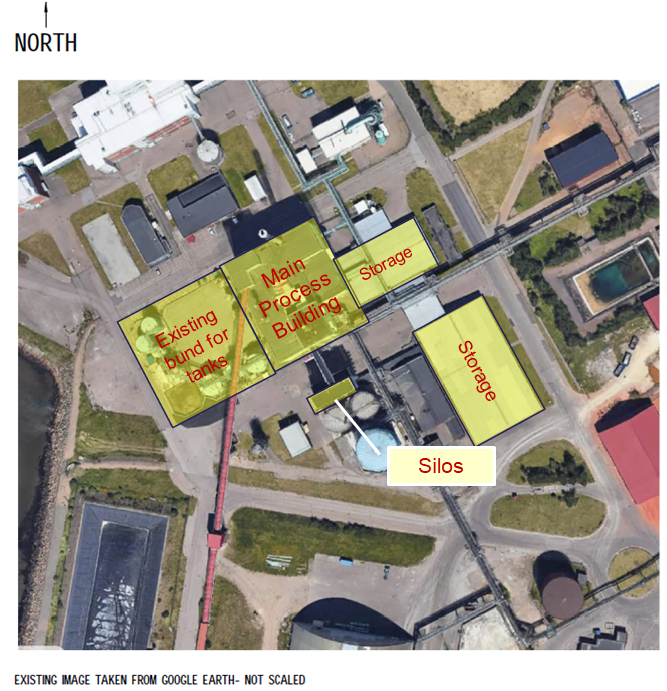

EasyMining is transforming an existing industrial site into Sweden’s first full-scale Ash2Phos plant. The facility, located within Kemira Kemi’s industrial area in Helsingborg, is being renovated to support large-scale phosphorus recovery and resource recycling.

The new plant will be fitted within an existing building located within Kemira Kemi's industrial area. The building, which is called the "Ecox building", will be partly reconstructed and adapted for EasyMining's future process operations. The work includes demolition, structural modifications, new openings, adjustments to facades and roofs, building extensions, and the installation of ventilation systems. A new switchgear room, updated electrical installations, and a control system are also being added.

In addition to the Ecox building, other nearby structures will be used to house parts of the process equipment.

Inside the modified buildings, approximately 450 pieces of equipment will be installed — ranging from reactors and process vessels to pumps, agitators, conveyors, tanks, and silos. More than 14 kilometres of process piping will also be fitted, primarily in smaller dimensions (DN25 to DN50), using stainless steel and GRP plastic materials.

Installing this equipment inside an existing building is one of the most complex parts of the project. The limited space, need for heavy lifts, and high level of coordination required make it a significant logistical and engineering challenge.

The existing Ecox Building.

It is not only the Ecox-building that will be re-used, also other buildings located in the direct proximity will be utilized for process installations.