Phosphorus, one of the key nutrients in mineral fertiliser and feed, is crucial for agriculture to be able to produce enough food. Today, Europe is highly dependent on phosphorus mined in a few other countries. This leads to large climate emissions, creates great supply risk, and makes the EU vulnerable to wild price fluctuations.

This is why we have developed Ash2Phos, a circular solution for recovering phosphorus from the sewage sludge ash, a reliably produced, renewable mineral concentrate produced in the course of wastewater treatment.

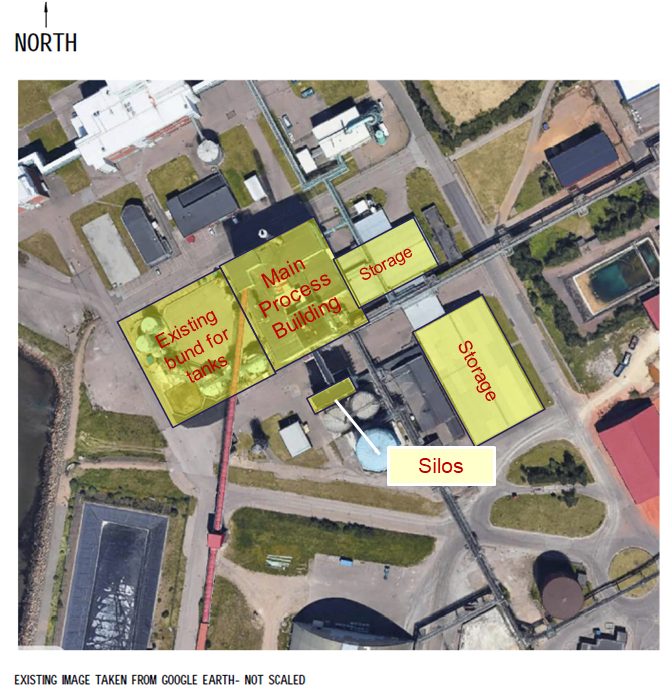

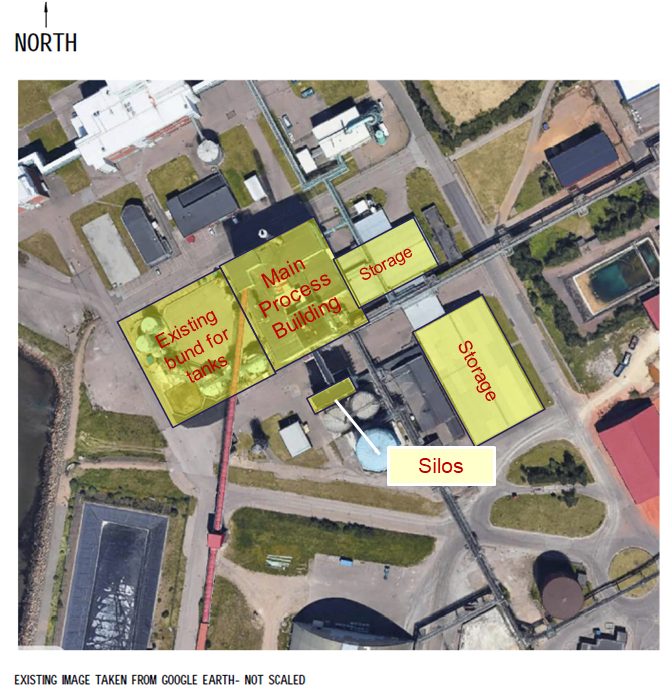

The new Ash2Phos plant will be fitted within an existing building located within Kemira Kemi's industrial area in Helsingborg. The building, which is called the "Ecox building" (Figure 1), will be partly reconstructed and adapted for EasyMining's future process operations. This includes demolition work, extensive structural additions, new openings and adaptations of facades and roofs, extensions, installation of building and process ventilation, new switchgear room and new electrical installations, a new control system and other necessary adaptations and additions.

The Ecox building has an approximate volume of 66 000 m3 and the existing internal floor surface is approximately 9 000 m2.

The existing Ecox Building.

It is not only the Ecox-building that will be re-used, also other buildings located in the direct proximity will be utilized for process installations.

The process equipment installations that will be fitted inside the modified existing buildings are extensive. Approximately 450 equipment items, large and small, consisting of reactors, process vessels, pumps, agitators, conveyors, different rotating machinery including tanks and silos will be installed. A large part of these equipment items are purchased in packages, meaning that they are procured as system deliveries.

Also, more than 14 kilometres of process piping will be installed, the majority in smaller dimensions (DN25 to DN50), in stainless steel and plastic piping (GRP).

Installing the process equipment inside an already existing building will be one of the largest challenges in the project, with the constraints this gives, heavy lifts and the installation coordination effort needed.